Strong Metal is committed to serving new energy vehicles, household appliances, rail transit and other industries, focusing on precision metal and plastic manufacturing. In order to better provide customers with one-stop total solutions and product services, we improve productivity by continuously introducing advanced equipment and accelerating operational efficiency. The company has independent research and development, design mold and manufacturing capabilities, the factory has: 80~1000 tons of large punching machine, fiber laser cutting machine, automatic welding robot, automatic injection molding, automatic painting and other types of equipment. With experienced process design team, production equipment and laboratory equipment, we can provide customers with the best solutions and technical support, and develop and progress together with customers.

Your Custom Metal Stamping

Founded in 2003, we are a multinational manufacturing enterprise. Headquartered in Shanghai, China, the company has five branches, and the factory addresses are: Shanghai, Taicang, Nantong, Nanjing, and Vietnam. The total registered capital is 120 million RMB, the total construction area of the plant is 30,000 square meters, and the number of employees is more than 500.

Factory Scale

Instant Quote

Competitive Price

Quick Sampling

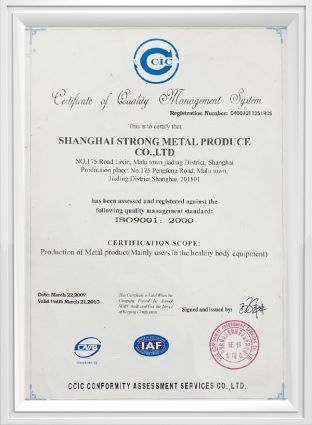

Quality Assurance

Delivery Guarantee